Overview

Air compressors are widely used in various industries. They convert the rotary mechanical energy output from the drive (motor or diesel) into the pressure energy of the gas, which is the core equipment for powering the pneumatic system. Commonly used are piston air compressors and screw air compressors

Principle

The screw air compressor is rotated in a cylinder by a pair of male and female rotors (or screws) that mesh with each other in parallel. The air between the rotor slots is continuously generated with periodic air-volume changes, and the air is transported from the suction side to the gas storage tank along the rotor axis to realize the whole process of suction, compression and exhaust of the screw air compressor. .

The screw air compressor generally adopts the star-delta starting mode to adjust the pressure by closing the intake valve. When the air pressure in the air tank (wind pack) exceeds the set pressure, the compressor intake valve is automatically closed, the compressor enters the unloading idling state, and when the air pressure in the air tank is lower than the set pressure, the compressor The intake valve is automatically opened and the compressor enters the loading state again. Due to changes in operating conditions, the amount of gas used varies, and the air compressor always repeats the “full load-unload” operation. At full load, the working current is close to the rated current of the motor. When unloading, the no-load operating current is about 30-50% of the rated motor current.

Therefore, the original system has the following problems:

1. Although the main motor is decompressed and started, the current during starting is still very large, which will affect the stability of the power grid and the safety of other electrical equipment.

2. The main motor is often operated at no load, which is a non-economic operation, and the power is wasted seriously.

3. The main motor has been running at a power frequency, resulting in a lot of noise when the air compressor is running.

4. When the main motor is started at the power frequency, the equipment has a large impact, the mechanical wear is serious, and the maintenance cost is high.

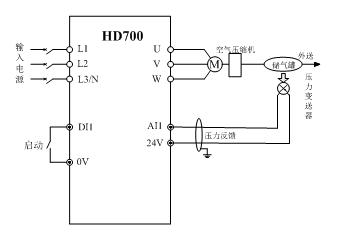

Third, seven-up inverter application program

The built-in PID function of the seven-up inverter can realize the closed-loop pressure control. The pressure signal fed back by the pressure sensor can adjust the output frequency of the inverter in real time to keep the pressure constant. If the air consumption is small, the inverter can automatically sleep and automatically wake up according to the pressure feedback value, and save energy by maximizing the constant supply of air.

1.PID constant pressure control

2. Communication control between inverter and controller:

Many air compressor controllers have built-in PID function to adjust the analog output signal (4~20mA) in real time. The inverter changes the frequency in real time according to the analog output signal of the controller to realize constant voltage control. In this way, the controller reads the frequency conversion in real time through communication. The output voltage, output current, etc. are displayed on the text screen for the user to view.

Plot controller and HD700 custom communication

The new generation of Plot controllers can be adapted to all drives that support the MODBUS RTU protocol. Various types of inverter communication protocols have been integrated inside the controller. When the inverter required by the user is not within the range of these models, the communication parameters can be set by themselves. The setup steps are as follows:

Enter the manufacturer parameter to move down the scroll bar to select the inverter model: set the inverter model to SELF-DEF. Return to the main interface, press the shift key, move the scroll bar to the manufacturer parameters, press the right shift key, enter the password (consult the air compressor supplier), enter the communication parameter setting interface with the inverter, set the output voltage, output current, output frequency. The Modbus address of the output power is set as shown below when using the HD700 inverter

4. the characteristics of the frequency conversion air compressor

1. Easy maintenance, saving energy and reducing operating costs.

2. Built-in PID control to improve the accuracy of pressure control,

3. Reduce mechanical wear and extend compressor life.

4. Realize soft start, reduce the impact on the power grid, and reduce the noise of the air compressor.